Maximo Visual Inspection Edge

Computer vision for manufacturing

The project: The idea behind this project was to create a computer vision based application to aid the manufacturing process in a variety of industries utilizing edge devices. This application ties closely together with another computer vision application I worked on, Maximo Visual Inspection. The goal is to utilize computer vision to quickly and easily detect visual defects, errors or problems that can occur during the manufacturing process utilizing edge devices such as iPhones or drones to do it.

My role: Senior UX Designer

The design team working on this computer vision manufacturing app consisted of a UX Researcher/Design Lead and myself as the Sr. UX Designer. My role as the Sr. UX Designer was to inform and design the user experience of the application to help make it easy to use for a variety of technical levels and experience around manufacturing. This included executives, managers and factory line workers.

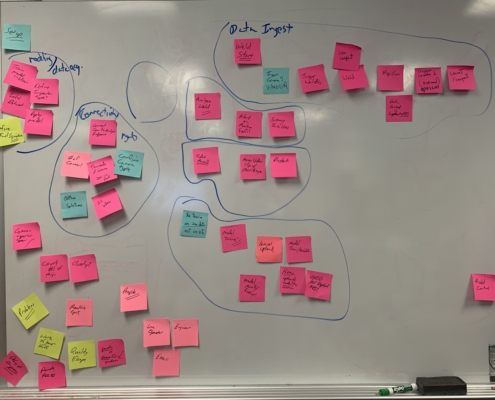

Design thinking workshop

Those working on this project knew very little about the manufacturing process and how computer vision might fold into it. Armed with information and feedback directly from current clients; sellers, developers, and designers gathered together for a two-day workshop.

During this workshop various design thinking strategies were utilized to gain alignment of expectations across the entire team. Big ideas, As-is scenarios, to-be scenarios and personas were all used to help get a better understanding of what the application might entail and how it could work at a high level.

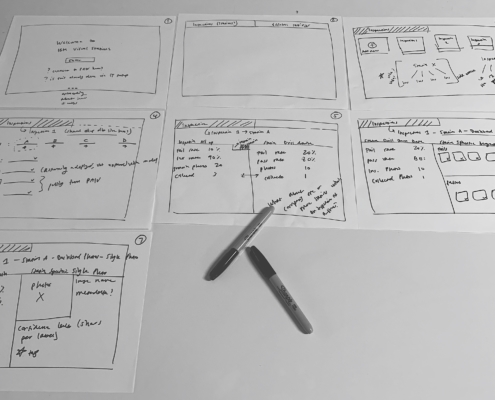

User feedback & low fidelity

To achieve success I worked very closely with the Design Lead to speak with and understand user needs and requirements. We spoke to sellers and clients to better understand their specific and individual manufacturing processes.

With this information I then started with basic, very generic low fidelity wireframes. These were used to confirm or refute assumptions. These ultra low fidelity wires were also used to spark conversation to further learn about how computer vision might be incorporated into the manufacturing process.

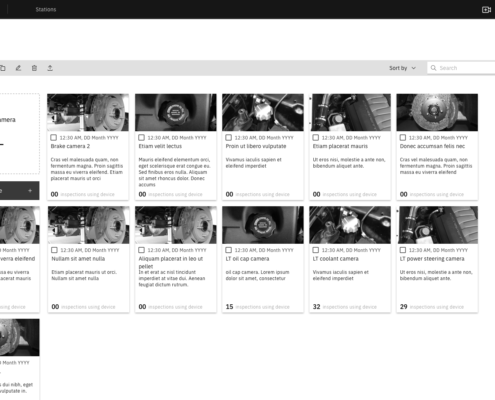

Mid-fidelity prototype and more discussion

After a few rounds of client feedback and discussions around the low fidelity designs, the team began understanding user needs better. From those initial rounds of user feedback, I worked on more mid-fidelity wireframe designs. The better fidelity helped to further drive discussions and feedback both with internal stakeholders and developers.

I put together a robust clickable prototype that covered the user flow from login to using the computer vision models for inspections during the manufacturing process. The application tied very closely with another computer vision application I worked on.